3D inspection of semi-flat products

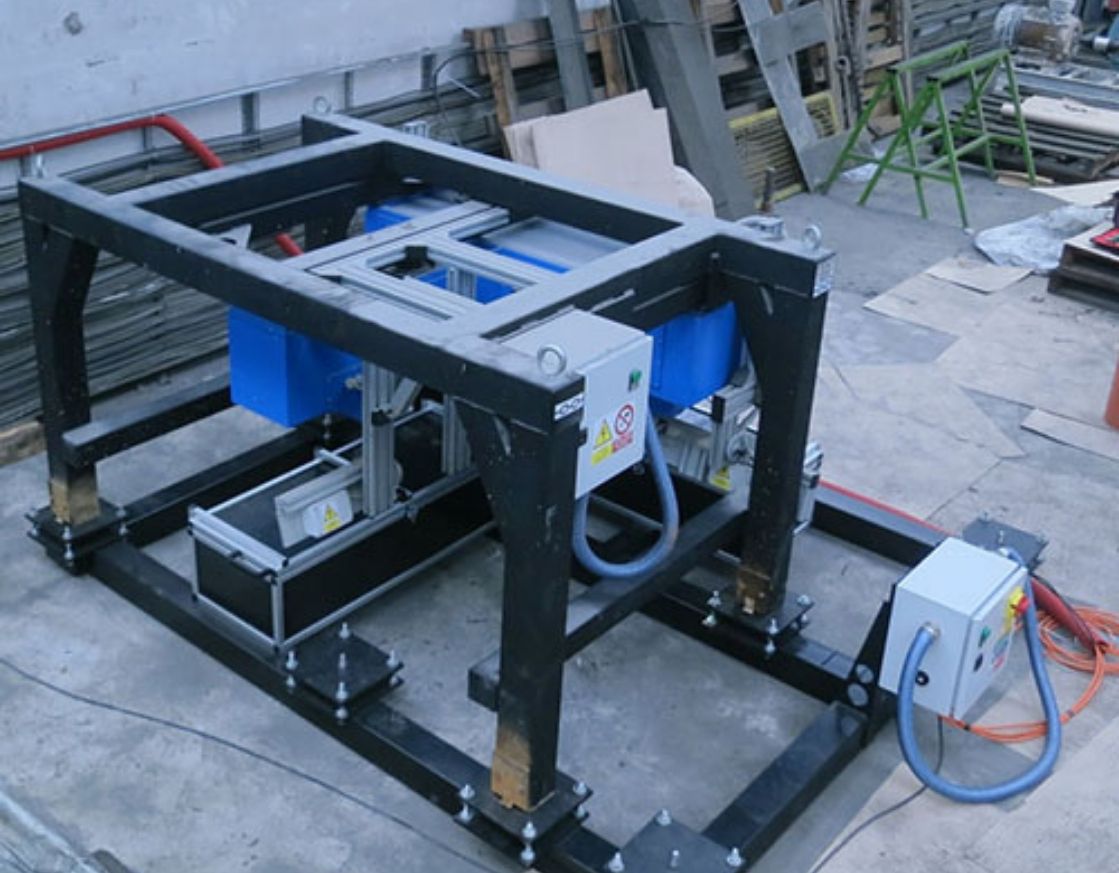

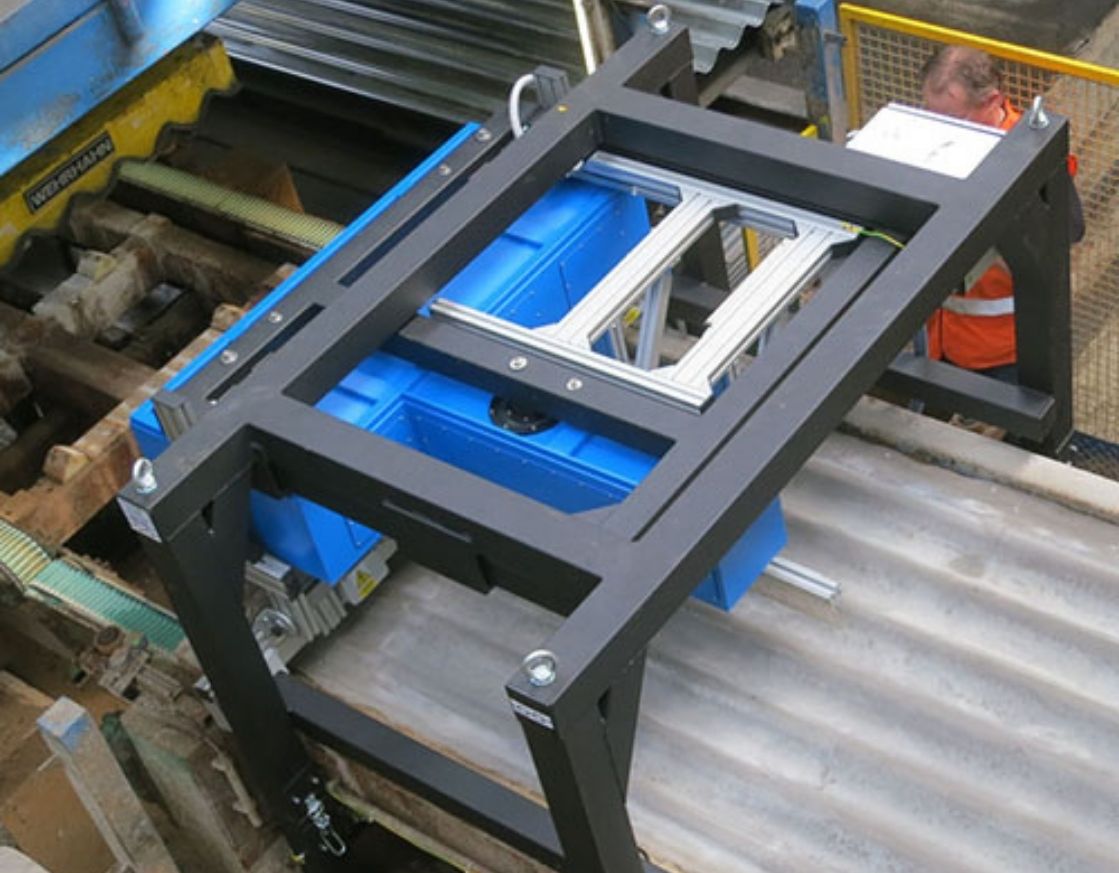

This type of device is designed for precise 3D measurement of surface dimensions of products on the lines but also in separate workplaces.

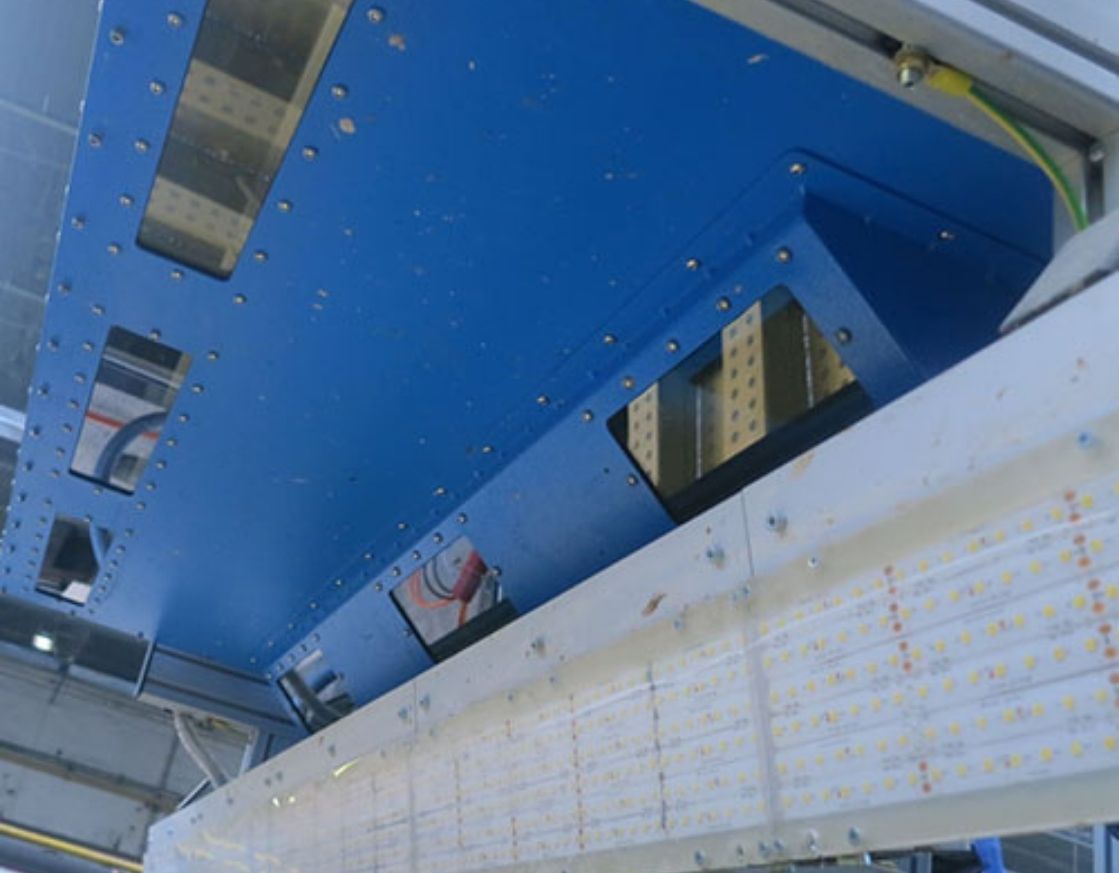

One of the applications of this type of measurement is for measuring fiber-cement cladding in the manufacturing process. In addition to checking the correct hole spacing in 2D, the height profile of the board is also measured. The 3D measurement sequence usually takes less than 5 seconds and runs even while the product is moving. The entire measurement takes place directly on the production line and the measured data is sent to a database for reverse production control. The scanned data is also archived for further statistical processing.

The solution also includes advanced 3D calibration of the device that runs on its own program. For operational verification of measurement accuracy, it is part of a verification tool that is built directly into the production line to minimize downtime of the production line to a minimum.

It is possible to measure various types of materials:

- Wood

- Cement

- Metal sheets

- Chipboard

- Plastic etc.

| Parameter | Value | Unit |

|---|---|---|

| Scanning speed | 30 | fps |

| Dimensions of the scanned area (W × L × H) | 1200×1300×200 | mm |

| Measurement accuracy | ± 0,3 | mm |

| Ambient temperature | 5 – 35 | °C |

| Communication interface | Ethernet | – |

| Degree of IP protection | 65 | – |