Measuringof Products with Industrial Robots

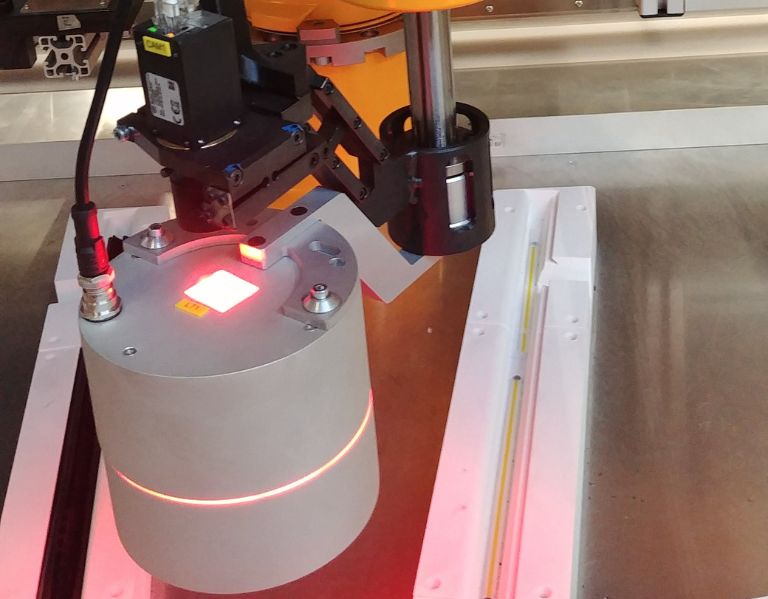

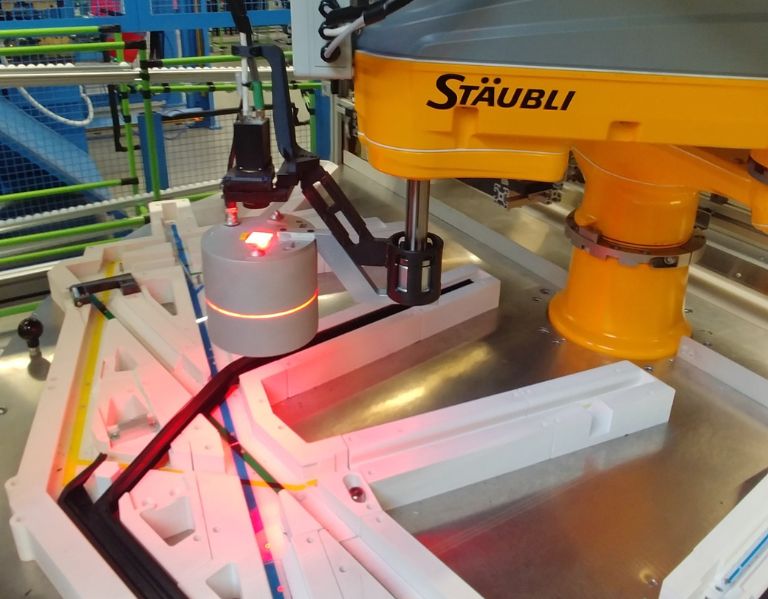

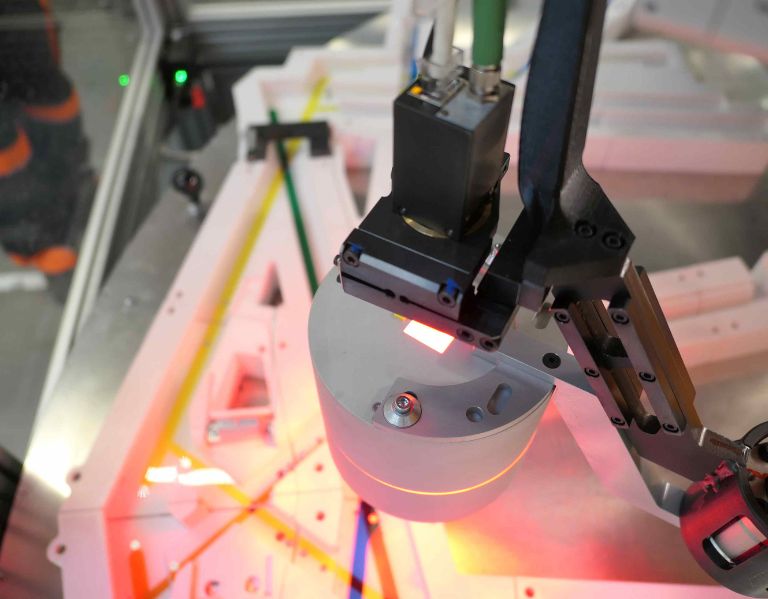

Combining a precise robot with a camera system can be advantageous for dimensional inspection of products.

An example of this application is the 2D measurement of products using a 4-axis SCARA robot

This is a carousel-type measurement station, where products can be loaded/unloaded from the station during the measurement process, reducing the overall inspection cycle time.

In addition to the robot and the camera head, the loading prism is an essential and integral part of the station. This is critical as it allows for the measurement of non-rigid products (such as rubber),, where the design of the product loader can directly affect measurement accuracy..

To achieve the required measurement accuracy of +/- 0.15mm, calibration was developed not only for the camera system but also for the robot and their mutual integration. The implemented solution ensures that the production line produces with the required dimensional quality, preventing issues during subsequent assembly on the production line.

The sequence and duration of the measurement depends on the number of dimensions to be checked on the product. Typical measurement time is approximately 1-4 seconds per dimension. The number of dimensions can be selected by the operator or specified by the technological specification. Captured data is archived for further statistical processing and can be sent to a higher level system for final value reporting.

The system is equipped with operational verification, ensuring regular device checks and release to production. Verification records are logged into the system, making it easy to demonstrate the correct operation of the equipment for audit purposes.

| Parameter | Value | Unit |

|---|---|---|

| Largest measured dimension | 1400 | mm |

| Camera resolution | 1600×1200 | px |

| Measurement Accuracy | from ± 0.1 | mm |

| Measurement speed per dimension | < 4 | s |

| Ambient temperature | 5 – 35 | °C |

| Communication interface | Ethernet | – |

| Automatic verification | Yes | – |