Pipetting Robot in 2 weeks? CIIRC CTU and others did it!

8. 5. 2020

(CIIRC CTU The Czech Institute of Informatics, Robotics and Cybernetics at Czech Technical University in Prague)

Under normal circumstances, a robot can take months or much longer to develop, yet with the Pipetting Robot, something very special happened. This pipetting robot, which was supposed to help test a large number of patients for the coronavirus, was developed in an incredible timeline of just 2 weeks. What lies behind this success?

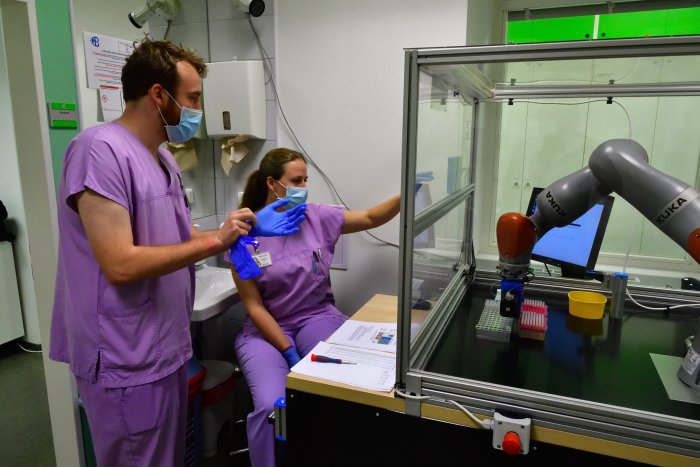

Photo by SEJKOT, CIIRC ČVUT

It started with a shortage

In the context of the COVID-19 crisis, testing a huge number of patients for the presence of the coronavirus was the biggest challenge we were faced with. Testing usually consists of pipetting activities that people from the hospital do manually. As a rule, however, there are only dozens of patients a week. But with the spread of the virus, hundreds of patients had to be tested every day. Robotic stations that are able to pipette are nothing new, but the crisis also made their use problematic. In order to function, they need a commercially produced mixture of chemicals, of which there was a shortage. Large scale testing called for innovation.

Pipetting

CIIRC CTU and others joined forces. It paid off.

The Czech Institute of Informatics, Robotics and Cybernetics (CIIRC CTU), The Institute of Nuclear Physics and, for example, JettyVision and many others participated in solving the problem. Together they came up with the idea of a pipetting robot. The Pipetting Robot did not need the mixture of chemicals that of which there was a shortage for its operation, but the one that is commonly used by laboratory technicians in pipetting was enough. The procedure was proposed by The Institute of Organic Chemistry and Biochemistry of the CAS, which is also able to produce the given chemicals.

From development to a functional prototype in 2 weeks

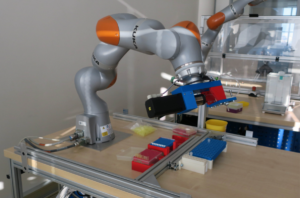

Then it was all a matter of weeks. Under the auspices of CIIRC CTU and with the support of other academic institutions, a top team of engineers, programmers and designers, who worked constantly, was formed. The variability of the team and experts from different specializations undoubtedly accelerated the development. The fact that all components, chemistry and know-how came from the Czech Republic also contributed to the acceleration. The pump needed for pipetting small volumes of liquids, for example, was supplied by The Nuclear Physics Institute of the CAS. It took the team only 14 days to develop, design, test and deliver a complete functional device capable of automatically pipetting samples. The functional prototype was ready in a week.

Developing the Pipetting Robot

Relief for hospital staff

The Pipetting Robot proved itself to be useful immediately. It is able to process up to seven hundred tests a day. With such numbers, precision and infallibility are important to avoid mixing patient samples. This is exactly what the Pipetting Robot had at its disposal. It thus brought relief to all the laboratory technicians, who would normally perform these activities manually. The Pipetting Robot is therefore a good example of academic institutes and small Czech companies flexibly responding to customer needs and quickly coming up with a functional solution at a time of crisis.

Are you also in need of solving a production or operational problem with the help of a specialized robot quickly? JettyVision is at your service!