Industry 4.0, jump on the wave of robotics

28. 3. 2020

Since 2011, global capacities have increasingly inflected the term “Industry 4.0”. It refers to the so-called fourth industrial revolution, which is to bring huge automation of production. However, although Industry 4.0 is still a long way off and automated production has its limits, it can already streamline and improve your production today. Do you know how?

Industry 4.0

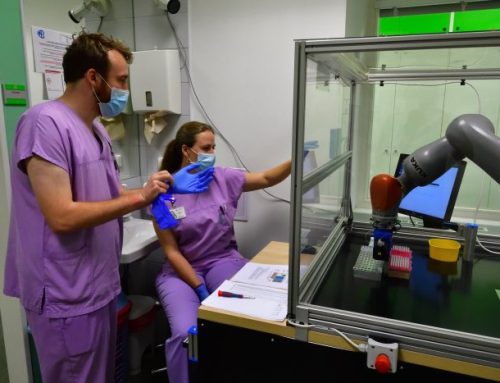

Industry 4.0 is the fourth industrial revolution, which entails enormous digitization and associated automation of production. Both of these phenomena are supposed to lead to a fundamental change in the labor market. Computers with new control / decision systems or robotic systems controlled by them should replace human power. This will apply in particular to simple and monotonous activities and mainly includes universal production lines, but applications are also possible in medicine, law and many more areas.

The emergence of the fourth industrial revolution

Industry 4.0 is set to launch rapid development in the following areas:

- communication technology,

- information and computer technology,

- cybernetics and artificial intelligence,

- materials engineering,

- biotechnology.

And new knowledge from these fields will lead to leap improvements in the tools that are used in the manufacturing sector of the economy:

- communication infrastructure (Internet of Things),

- big data analysis,

- autonomous robots,

- data storage and cloud computing,

- simulation and virtualization,

- 3D printing,

- augmented reality,

- multiagent systems,

- (smart) sensors.

About Industry 4.0

The change should involve mainly the fact that all production facilities will be connected to cyber-physical systems. Every element in production (e.g. conveyor, robotic arm, semi-finished product) will “know” what it is, and what its task and history is. The tools will be able to configure, optimize, diagnose themselves, and in addition, support production operators. It is also expected that all autonomous units will be able to communicate, negotiate and cooperate with each other on a continuous basis.

In order for this collaboration to take place, although some elements cannot even communicate on their own, all agents must be represented by software modules / agents that act on their behalf and instead of them. Another feature of Industry 4.0 is the so-called horizontal integration of production systems – their interconnection across the supply chain from suppliers through manufacturers to distribution to the end-customer and subsequent service.

Contribution of Industry 4.0

One of the main benefits of this revolution is the unprecedented transformation of society as a result of increased productivity in production processes. At the same time, unfortunately, a large number of work activities will disappear, but new professions will appear. It will therefore be reflected in the necessary change in education. But whatever it is, one thing is now for sure, smart sensors, with which we have had 20 years of experience, can improve and streamline your production today already. The same goes for robotics and camera systems. In addition, production makes all this more independent of the health or availability of workers, which is more important today than ever before.

Are you interested in automation or improving and streamlining your production? Contact us, we will be happy to advise you.