Quality inspection of mineral wool production

Detection of temperature defects of hot products.

Our measuring system provides operators with detailed, real-time information about the products moving through the line. With advanced detection of temperature extremes, it can quickly identify potential defects and enhance control over the final product’s quality.

The user-friendly interface displays the current captured image of the product along with a visualization of the last detected defect. The system accurately pinpoints the location of defects and offers statistical data that helps optimize processes and improve production efficiency.

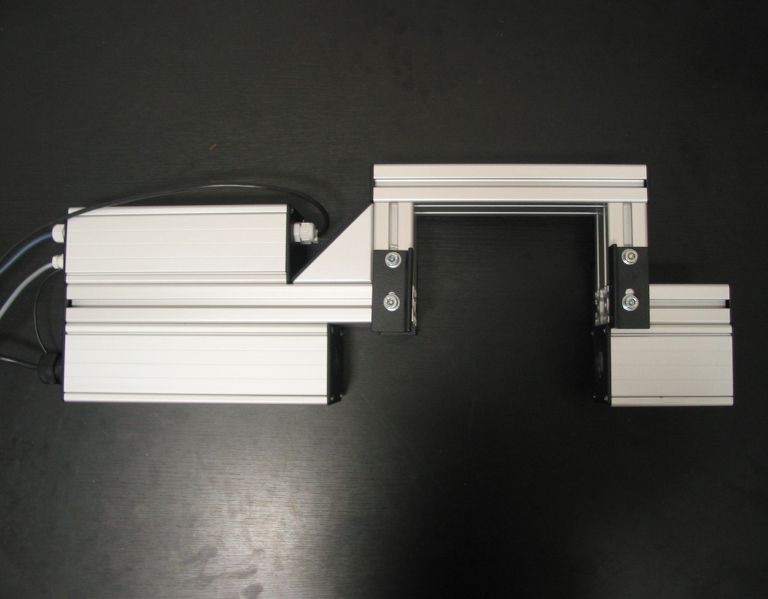

Maintaining the highest standards of cleanliness for the optics is crucial. Our specially designed air purge system excels in dusty environments, ensuring that with this innovative visor protection solution, you can achieve several months of operation without needing intensive maintenance or cleaning.

For connectivity, the system can be linked to a superior system or PC using Ethernet over distances up to 100 meters. For distances exceeding 100 meters, optical cable is used.

| Parameter | Value | Unit |

|---|---|---|

| Scanning velocity | 30 | fps |

| Scanned area dimensions (w×l) | 2000×1500 | mm |

| The smallest recognizable defect | 20×20 | mm |

| Ambient temperature | 0 – 50 | °C |

| Degree of IP protection | 65 | – |

| Communication interface | Ethernet | – |

| Power supply method | trough Ethernet | – |