Measurement and Inspection of Red-Hot Products

Precise measurement and inspection of red-hot products are essential for quality assurance in industrial processes. Our method utilizes the product’s own radiation, providing an effective solution for various applications.

How Does It Work?

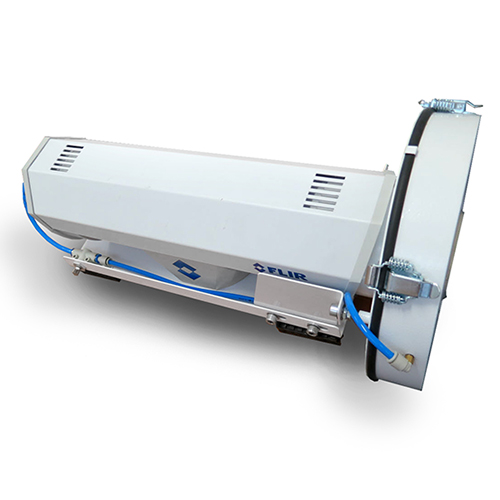

Our method employs the product’s own radiation, which is detected using specialized optics. This allows for accurate capturing of the contours of the glowing product and precise measurement of the necessary parameters based on this data. Another effective approach involves thermal imaging, which enables measurements even at lower temperatures than those at which objects glow. This system also analyzes temperature fields, offering a comprehensive overview of the measured object.

Why Choose Our Method?

- High Accuracy: Measure contours and temperature fields for detailed analysis.

- Measurement Flexibility: Measure even at low temperatures by thermal imaging.

- Wide Range of Applications: Ideal for use in metallurgical and glass manufacturing, building materials production, welding, and hot runner monitoring.