Dimensional control

Are you struggling with inaccuracies in your manufacturing processes and facing costly claims due to incorrect product dimensions? Unlock the true potential of your product range by embracing our cutting-edge technologies for precise measurements.

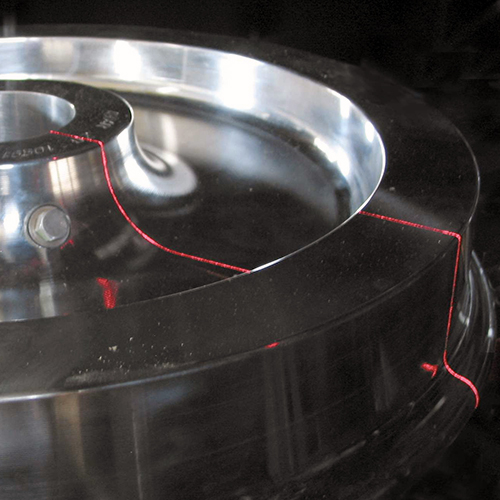

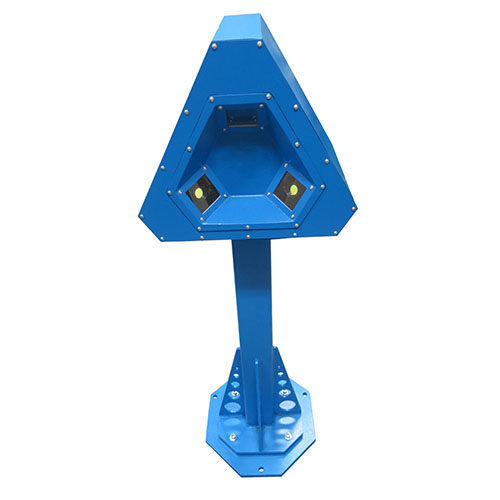

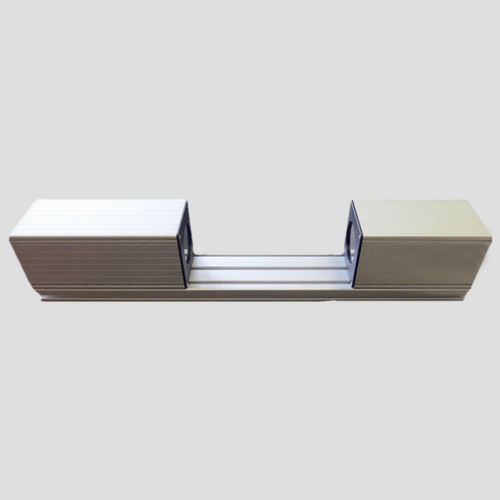

Camera systems designed for dimensional inspection of both flat and three-dimensional products typically capture and evaluate specific parts of a product (such as an area or desired geometry), ensuring high accuracy and consistency throughout the manufacturing process. This approach allows you to maintain high quality in production while optimizing the manufacturing process for maximum efficiency. By minimizing complaints, increasing productivity, and saving time and money, you can enhance your overall operations.

Our advanced dimensional inspection technology is designed to enhance your measurement processes with remarkable capabilities:

- 2D and 3D Measurements: Our system excels not only in 2D tasks but also can seamlessly transition to 3D with proper calibration. This means you can capture not only the shape of the object but also critical depth information, providing a comprehensive view of your products.

- Unmatched Measurement Accuracy: With a target precision of ±0.02 mm, our technology ensures an exceptional quality of measurement, delivering robust and consistent results that you can trust for your quality assurance needs.

- Versatile Measurement Options: Our system allows for measurements during rotation, linear movement, or while stationary, giving you the flexibility to adapt to various operational conditions.

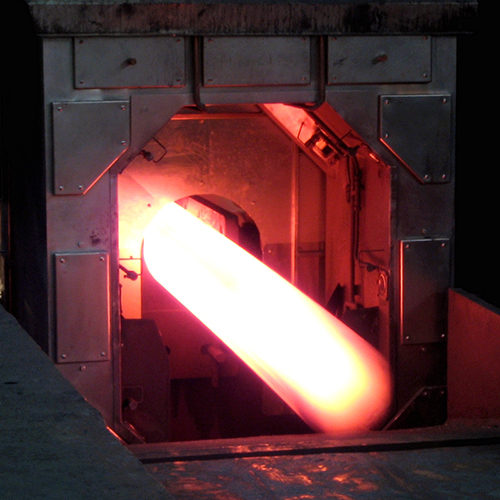

- Independence from Material and Color: No matter the surface material or color, our technology can accurately measure geometric features, ensuring that you can maintain quality control across your entire product line.

Using a combination of both front and back lighting along with laser triangulation, we can easily and accurately measure the dimensions of a wide variety of both hot and cold manufactured products. Our advanced vision systems are designed to seamlessly integrate with your existing operations, providing you with a straightforward way to improve efficiency and precision in your manufacturing process.